Loading...

Our company is focused not only on welding tables! The dynamically developing metallurgical industry has led us to expand our company's operations. Thanks to this, we can offer you a range of other services and products.

At present, FraMa-BT offers complete metal machining - from precision laser cutting, bending details to MIG/TIG welding and powder coating. Many years of experience in this industry results in the best quality and the possibility of offering an attractive price for order execution. Our team always ensures that the execution of orders runs smoothly and without failures. Our professionalism is confirmed by the ISO-2768-1 certificate - the quality guarantee of products we offer.

Sheet metal bending with the use of the TruBend 5170 bending brake

Pressing force: 1700 kN

The length of bending edge: 3000mm

Opening: 615mm

Sheet metal cutting with the use of TruLaser 3030 fiber laser cutter

Working surface: 3000mm x 1500mm

Maximum thickness of sheet metal::

Constructional steel: 20mm Stainless steel and aluminium: 15mm

We offer a professional powder coating service of various types of elements. The paints we use ensure excellent coverage and high durability of the coating.

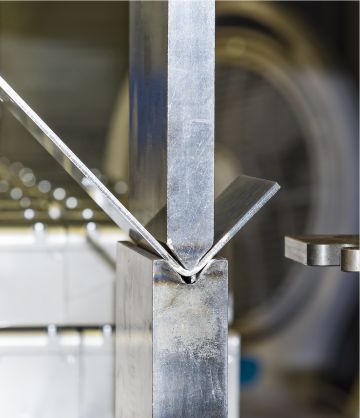

Using the MIG/MAG method, we can obtain good weld quality and high welding efficiency. This method gives us the opportunity to weld elements characterised by a wide range of thicknesses and also the ability to weld in all positions.<

The TIG method enables obtaining an extremely clean and high quality weld. It is most often used for welding stainless steels and other high-alloy steels as well as such materials as aluminum, copper, titanium, nickel, etc.